公司简介

ficonTEC provides automated micro-assembly and testing solutions for the photonics industry. These solutions are realized as cutting-edge, semi- or fully-automated production systems, regardless of the device material and of the specific application the device is targeting. Our modular system architecture is additionally scalable, so that exploratory, proof-of-process assembly as well as high-volume assembly and test requirements are addressable – and anything in between.

产品列表

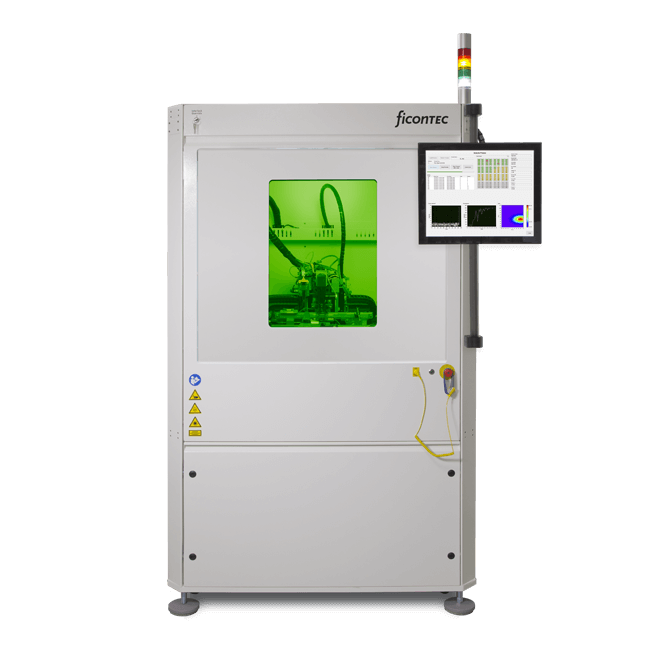

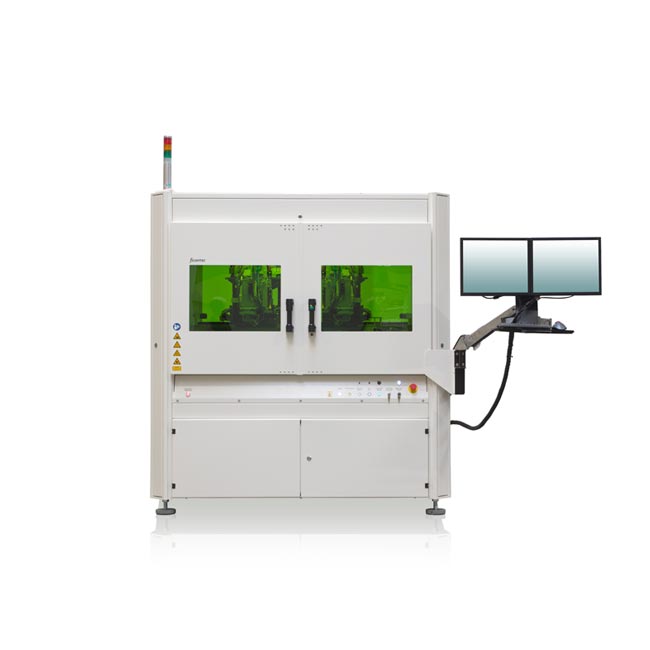

Automated Photonics Assembly – ASSEMBLYLINEHigh-precision, fast-active alignment stand-alone and in-line assembly solutions designed for automated production (‘align-&-attach’) of photonic devices. They uniquely combine active alignment capabilities and flexible attachment configurations with a tried and tested software control interface, all in an industry-proven design. Optional modules provide additional features (multi-functionality), with the high-end models providing automatic tool changing, beam testing capability and wafer processing. All AssemblyLine machines utilize our AutoAlign multi-axis motion systems (see below) – high-end stages with multiple degrees-of-freedom (from 3 up) combined with state-of-the-art real-time motion controllers, guaranteeing easy and accurate sub-µm pivot-point positioning. Stand-alone machines: ficonTEC’s stand-alone ASSEMBLYLINE machines are designed to provide as much multi-functional, multi-step align-&-attach assembly capability as possible in a single cell format. These machines are best suited to complex production requirements requiring multiple process steps within a single machine system. In-line machines: ficonTEC’s new, next-generation ASSEMBLYLINE machine systems utilize a re-designed housing format and state-of-the-art feed-in/out capabilities in order to be production-(in)-line-capable from the ground up. They can be supplied individually as a versatile production cell designed to slot into an existing or proposed production line. Alternatively, they can be supplied in combination with additional functional type systems as task-optimized production segments. Availability: Stand-alone as AL300, AL500/AL1000, AL2000 and as an entry-level A300-series system. In-line from A400 and up.

|  |

Automated Fiber-Optics Assembly – FIBERLINEFIBERLINE machines are high-precision, fast-active align-&-attach systems ideally suited for fiber-optic and waveguide-based components and devices, including fiber ribbon/arrays and silicon photonics. Various alignment lasers can be configured when attaching fibers to passive optical component such as photodiodes, PLCs, or AWGs. The wavelengths needed can be chosen from the typical bands around 1310 nm or 1550 nm. For fiber arrays multiple lasers can be controlled simultaneously. All common fiber connector types are catered to. Like the ASSEMBLYLINE systems, FIBERLINE also utilizes our AutoAlign multi-axis motion systems (see below) – high-end translational and rotational stages with multiple degrees-of-freedom (from 3 up to 12 or more) combined with state-of-the-art real-time motion controllers, guaranteeing easy and accurate sub-µm pivot-point positioning and alignment. The F1200 system makes use of the new in-line housing format, with all the benefits that brings (see ASSEMBLYLINE above), and also enabling a ‘re-configure & re-purpose’ pathway for continued use following product ‘end-of-life’. FIBERLINE‘s modular and expandable concept is customizable with a range of optional modules providing additional functionality, including testing or qualification. Automated fiber handling functionality is available in other product lines on request. |  |

Automated Precision Die Bonder – BONDLINEPrecision die bonder cells focused on passive high-resolution chip/die positioning coupled with thermal attachment (position-&-attach), with accuracies down to the micron and even sub-micron range. Feature-rich functional modules provide thermal management, multiple bond force modes and eutectic/epoxy/soldering attachment capability, thus catering to a wide range of individual bonding requirements. BONDLINE is intended for chip-on-submount (CoS), MEMS/MOEMS and sensor assembly, as well as for other optical components, including laser diodes and hybrid assemblies on silicon photonics and other PIC devices. Optional modules provide additional features (multi-functionality), with the high-end models providing optional automatic tool changing and wafer processing capability. Stand-alone machines: ficonTEC’s stand-alone BONDLINE machines are designed to provide as much multi-functional, multi-step position-&-attach capability as possible in a single cell format. These machines are best suited to complex production requirements requiring multiple process steps within a single machine system. In-line machines: ficonTEC’s new, next-generation BONDLINE machine systems utilize a re-designed housing format and state-of-the-art feed-in/out capabilities in order to be production-(in)-line-capable from the ground up. They can be supplied individually as a versatile die bonder cell designed to slot into an existing or proposed production line. Alternatively, they can be they can be daisy-chained with additional functional type systems as a series of task-optimized systems for extended production segments. In principal, even entire production lines can be envisaged. Availability: Stand-alone as BL300, BL500/BL1000 and BL2000 and as an entry-level B300-series system. In-line from B400 and up.

|  |

Adaptable Die Bonder Platform CUSTOMLINESporting the largest range of optional modules available to any ficonTEC machine system, the CustomLine (previously known as CompactLine) is our most adaptable and versatile die bonder platform. These machines are designed to provide diverse ‘quasi-off-the-shelf’ pre-configurable solutions for customers in the semiconductor and photonics assembly and packaging sector. Comprising modular, multi-purpose die bonder cells, CustomLine can be configured for a broad range of tasks in a wide range of industrial production environments. The base systems include a pre-configured, high-precision gantry motion system that carries the tools for die bonding, beam testing capability and/or wafer handling, and already provide everything needed for an outstanding range of applications. A variety of configurable functional modules together with clean-room compliance (ISO 6) makes the system an ideal, general-purpose and industry-capable photonic device production cell. Currently available as stand-alone systems, providing optional automatic tool changing and wafer processing capability. Designed for industrial production environments and especially suited to new product introduction (NPI). Availability: Stand-alone as CL1500/2000. In-line formats form part of the product roadmap. |  |

Opto-electronics Chip Tester – TESTLINEFully-automated test systems for full LIV testing as well as spectral and near-/far-field beam characterization of single laser chips, VCSELs, unmounted laser diode bars, and chip-on-submount (CoS) sources. Also available for a variety of other complex tasks, including singulated chip testing, automated optical inspection, and more. High-end models can be equipped with an optional wafer table for wafer-level testing tasks. A more recent addition to TESTLINE capability is compatibility with PXI-based optical instrumentation modules that leverage National Instruments’ LabVIEW graphical programming environment, making integration seamless and enabling the creation of sophisticated and fully-automated, combined electro-optical test solutions to match individual requirements. A similar goal can also be achieved within non-LabVIEW and alternative instrumentation environments using modular benchtop and IOT-focused test equipment. Stand-alone machines: ficonTEC’s stand-alone TESTLINE machines are designed to provide as much multi-functional test-&-qualify capability as possible in a single cell format. These machines are best suited to complex testing requirements requiring multiple steps within a single machine system. |  |

Fully-automated Inspection – INSPECTIONLINEFully-automated, multiple-camera-based systems available for a variety of complex and thorough inspection tasks, achieved by acquiring high-resolution pictures of all surfaces of interest and performing optical inspection based on the user’s criteria. Available with side, top and bottom wall camera-based inspection modules. Intended also for use with coated facets of semiconductor chips and PICs. Wafer table option available. Different feeding philosophies are optionally available. Availability: Stand-alone as IL2000. |  |

Laser Diode Bar Stacking – STACKLINEA unique machine providing fully-automated stacking and/or unstacking of laser diode bars. It can handle any combination of laser bars and spacers (dummies), generating flush or staggered stacks. It can be optionally equipped with fully-automated visual device inspection for sorting bars into the designated GelPaks or WafflePaks based on the inspection results. Availability: Stand-alone as SL2000. |  |

Laser Welding – WELDLINEA 2 or 3-beam vertical configuration laser welding machine cell utilizing a fiber-coupled Nd:YAG laser and additionally featuring automatic alignment, device characterization and testing capabilities as well as sophisticated component tracking throughout the entire machine process. As standard the system includes ficonTEC‘s exclusive AccuView target viewing laser processing heads. Availability: Currently stand-alone only. |  |