EO Technics Co., Ltd.位于韩国安养,成立于1989年,主要从事开发和生产用于半导体、显示器和PCB制造工程的激光和设备。

产品列表

Semiconductor

HOME > Products > Equipment > Semiconductor

Marking

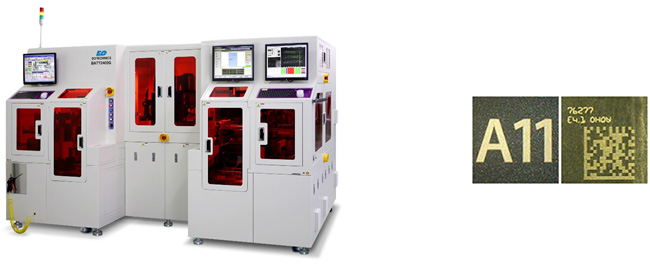

Strip marker

(2 beam/4 beam marker)

The 4-beam strip marker for semiconductor can support both slot and stack magazine for loading & unloading. The strip handling is divided into two types, shuttle and rail types and the loading/unloading methods such as 1 in 1 out, 2 in 2 out and etc. can be configured in accordance with customers' request.

| Shuttle type | Placing the strips on the shuttle for handling |

|---|---|

| Rail type | Moving the strips along the rail with indexing motors; faster transfer |

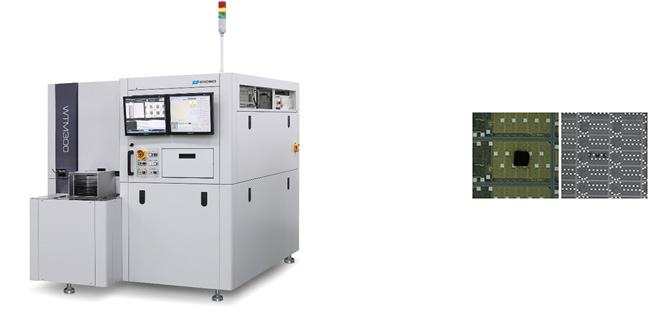

Tray marker

(2 beam/4 beam marker)

Tray marker for semiconductor can be manufactured as compact ‘U’ type and conventional "I" type.

| U type | Small footprint, easy to operate with short tray movement distance |

|---|---|

| I type | Available for the large-sized lasers |

Wafer back side marker

CSM3200/3300

CSM series is the wafer level chip scale marker for semiconductor and can mark on wafer backside without any chip damages.

The equipment has an automated calibration system to compensate scanner accuracy and an automated marking inspection system to check the marking results.

| Combo type | Applicable for both FFC and bare wafer in single equipment. |

|---|

Wafer top side marker

WTM200/300

WTM series is for marking reference die, bad die and wafer ID on a wafer.

It provides wafer top side marking solution with high-speed processing and a user-friendly program

Wafer ID marker

WM080/012

WM series is wafer ID marking system used in cleanroom.

It has high-degree stability and high-speed processing.

It also has OCR edit function which the user can edit by themselves.

Grooving & Dicing

LMC3200G/LMC3200D

Grooving - LMC3200G removes the low-k material and metal pattern layers on the wafer sawlane.

It not only improves the yield rate but also reduces wafer chipping during

the blade dicing processing.Dicing - LMC3200D is a dicing system for thin wafer of less than 200㎛.

It is better than mechanical blade dicing system in terms of COO, sicne it doesn’t need to replace

blade and the lifetime of laser parts is long and semipermanent.

The non-contact process can dramatically reduce the problem of chipping and enable high-speed

processing.

Cutting

PKG cutting

BMC254

It is a package cutting equipment for substrates.

The higher accuracy can be achieve by using alignment vision and automatic scanner compensation feature.

It provides good quality performance and high productivity with flying processing method.

Drilling

PoP drilling

BMC204P

BMC204P is a package drilling equipment for the strip and wafer types of POP.

Its automatic inspection and scanner compensation feature make the process highly accurate.

It adopts flying processing method to increase productivity.

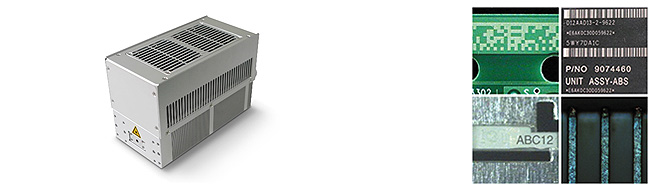

Fiber

HOME > Products > Laser > Fiber

Fiber laser

EF20P-QSF/EF20P-LMF

EF20P-QSF : Maximun 20W output, Q-switched pulsed fiber laser with 1mJ pulse energy. Compared to

state laser, the fiber laser is compact size and has less influence on working conditions.

Fiber laser is optimized for laser marking on semiconductor and general materialsEF20P-LMF : 20W pulsed fiber laser with 0.7mJ pulse energy. It modifies processing conditions depending on

customer requirements and specifications.

Pulse width modulation range 4 ~ 1,000ns of seed LD allows EF20P-LMF to

process various materials such as plastic, ITO, and metal.

EF40

Average 20W green wavelength pulsed fiber laser.

It modifies processing conditions depending on customer requirements and specifications.

Pulse width modulation range 4 ~ 1000ns of seed LD allows EF40 to process a wide various materials such as plastic, ITO, and metal, wafer etc.

EF500C/1000C/2000C

EF4000C/6000C

CW fiber laser technology has advantage of its stability and low-cost operation compared to high power solid-state laser.

It offers cutting and welding solutions for various thickness of metal.

It has superior beam quality and high performance.

Depending on the length of fiber transmission, it has the advantage of being able to easily process far-distance materials.

RCF (Ring Core Fiber)

EF4000RC

RCF is a special fiber laser that has a center beam and a ring beam.

It reduces the spatter with a laser beam from dual-core.

Each fiber has maximum 4kW output from center beam and ring beam at the same time and 80% more effective than a general fiber laser for reducing spatter.

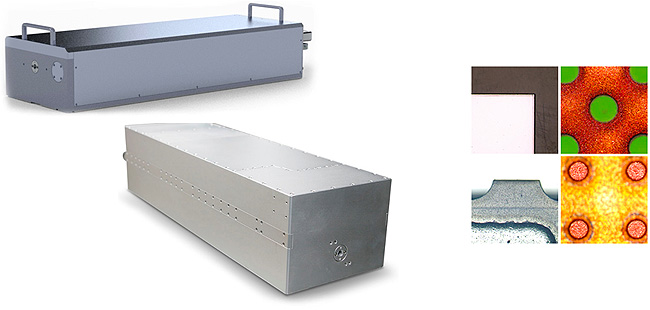

DPSS

HOME > Products > Laser > DPSS

ns laser

EV10/EV10G

EV10/EV10G is diode pumped solid-state laser for general marking and applications such as wafer marking and photovoltaic scribing.

It guarantees quantum efficiency, stable output power, and long lifetime operation by adopting end-pumping method.

The laser is air cooling system and designed to set up any handlers and in-line systems.

V20/V20G/V30

V20/V20G/V30 is next-generation laser technology-based marking device.

It shows excellent performance in high speed marking, engraving, and etching.

Green marker is suitable for LED package marking and offers the best solution for micro precision marking.

LV100/LV150

LV100G/LV150G

LV100 /LV150 / LV100G / LV150G is solid-state ns laser of end-pumped type.

LV100G and LV100 are green and UV wavelength each and well-designed for metal, semiconductor cutting and PCB drilling equipment.

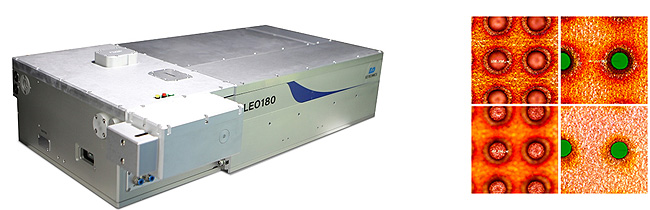

LEO180n

LEO180n is high qulaity & high power Hybrid type laser that combined fiber laser with solid-state laser.

The laser covers not only IR and UV wavelength but also Green and offers high quality with pulse control technology.

It is suitable for high speed processing with high output stability and high repetition rate operation of hundreds of kHz.

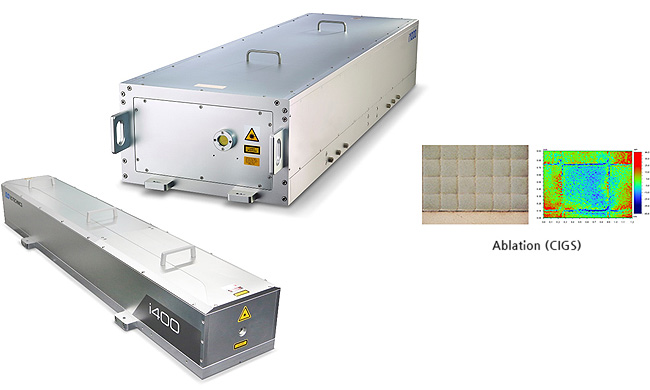

i200/i400/i1000

i200/i400/i1000 is diode-pumped solid-state laser.

It provides 400W ~ 3200W output power at the 1064nm wavelength and generates maximum 3 kW peak power.

It has robust head and customized control system which appropriate for OEM equipment and industrial applications.

g200/g400

g200/g400 is diode-pumped solid-state laser with high average output power and pulse energy at 532nm wavelength.

It offers the best platform for the most industrial applications using robust head and customized control system.

u40/u80

u40/u80 is diode-pumped solid-state laser.

It provides up to 180W high power at the 355nm wavelength.

It offers the best platform for the most industrial applications using robust head and customized control system.

ps laser

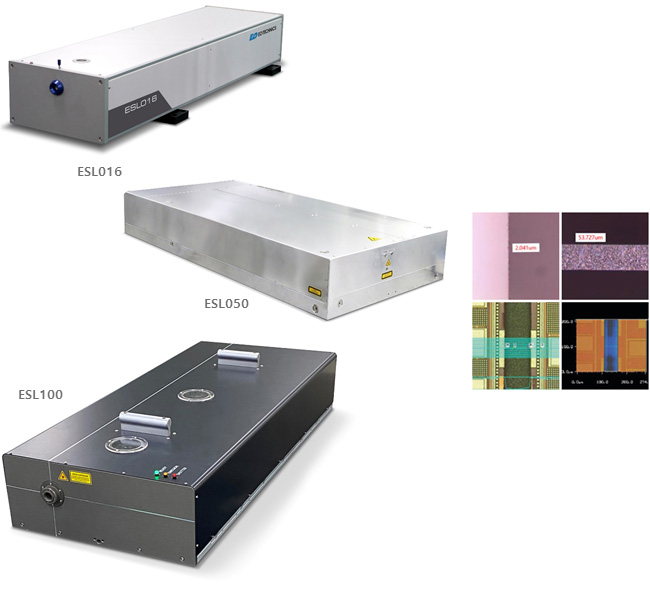

ESL series

(ESL016/020/050/100)

ESL Laser is picosecond laser with short pulse width less than 15ps and 10W ~ 100W average power.

The laser covers IR and UV wavelength and offers high performance.

It has high quality beam with stable output and pulse control functions.

fs laser

LEO10f

LEO10f is optical fiber femtosecond laser with 10W average power and below 400fs pulse energy.

It is suitble for ultra fine processing with high peck power.

It offers laser solutions for various applications by modulating IR, Green, and UV wavelength.

DDL

HOME > Products > Laser > DDL

DDL

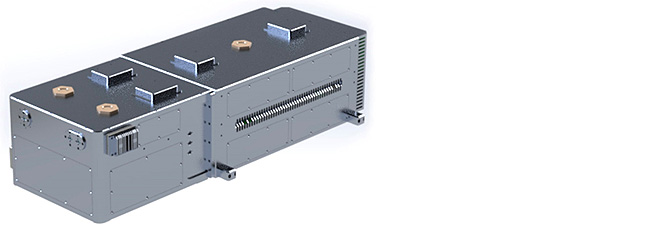

ED100~1000

ED2500/ED4000/ED6000

ED series is highly effective laser with compact size and able to use stably in the range of from hundreds of watts to hundreds of kilowatts.

Applicable to a wide range of process, including soldering and plastic welding.

Can select CW or QCW operation, and air or water cooling system.